Decoding the Complexity: An Overview of Modern PCB Assembly Techniques

Learn about our state-of-the-art Surface Mount and Through-Hole Technologies, sophisticated soldering processes, and rigorous quality control methods that define today's industry standards.

The Sophistication of Modern PCB Assembly

In the world of electronics, Printed Circuit Board (PCB) assembly represents a remarkable fusion of innovation, precision, and complexity. Since Profab Electronics was founded in 1993, we have been at the cutting edge of this field, continually adapting to and embracing the rapid evolution of PCB assembly techniques. This article offers a high-level overview of the sophisticated methods that define modern PCB assembly, showcasing the intricate processes and technologies that are integral to producing the electronic devices that power our world.

Today's PCB assembly is a far cry from the manual and time-intensive processes of the past. It's a field characterized by micro-scale components, advanced automation, and stringent quality requirements. Through this exploration, we aim to unveil the complexity behind these modern techniques, illustrating how Profab Electronics expertly navigates this intricate landscape to deliver superior quality products.

The Essence of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) stands as a cornerstone of modern PCB assembly, allowing for more components to be placed on a board than ever before. This technology has revolutionized the industry by enabling the production of smaller, more compact devices, without compromising on their functionality or power. The ability to place tiny components on the surface of the PCB has been a game-changer, leading to a significant increase in circuit density and the capability to design more sophisticated electronic devices.

At Profab Electronics, our SMT process is fine-tuned for precision and efficiency. We employ advanced pick-and-place machines that are capable of placing components with incredible accuracy and speed. These machines handle components with delicate care, placing them precisely on designated spots on the PCB. This accuracy is crucial, as the components we work with are often minuscule and require meticulous handling. Coupled with our high-speed assembly capabilities, we can meet large volume orders while maintaining the highest quality standards, ensuring our clients receive products that are both reliable and produced efficiently.

Through-Hole Technology: Reliability in Connections

Despite the dominance of SMT, Through-Hole Technology (THT) maintains its relevance in modern PCB assembly, especially for components that demand stronger mechanical bonds. In THT, component leads are inserted through pre-drilled holes on the PCB and then soldered to pads on the opposite side. This technique provides robust connections, making it ideal for components that must endure physical stress or high-power applications.

At Profab Electronics, our approach to PCB assembly is versatile, combining the best of SMT and THT to cater to a diverse array of client needs. This hybrid technique allows us to handle a wide spectrum of component types and assembly requirements. We can integrate the high-density, space-saving advantages of SMT with the durability and strength of THT. This flexibility is a testament to our commitment to providing comprehensive solutions, ensuring that our PCBs perform optimally in various environments and applications.

Advanced Soldering Techniques: The Heart of PCB Assembly

Soldering, the process of joining electronic components to the PCB, has seen significant advancements over the years. Today's soldering techniques, such as reflow soldering for SMT and wave soldering for THT, require a high degree of precision and control. These methods involve melting solder in a way that it forms a strong and reliable bond between the component and the PCB. The accuracy of temperature control and timing is crucial in these processes, as it directly affects the quality of the solder joint.

Our team at Profab Electronics excels in these advanced soldering techniques. We employ automated soldering processes that are meticulously monitored and controlled, ensuring consistency and perfection in every solder joint we create. This level of precision is essential in reducing defects like cold solder joints or solder bridges, which can compromise the functionality and reliability of the PCB. Our commitment to excellence in soldering is a key factor in our ability to deliver PCBs that meet the highest standards of quality and reliability.

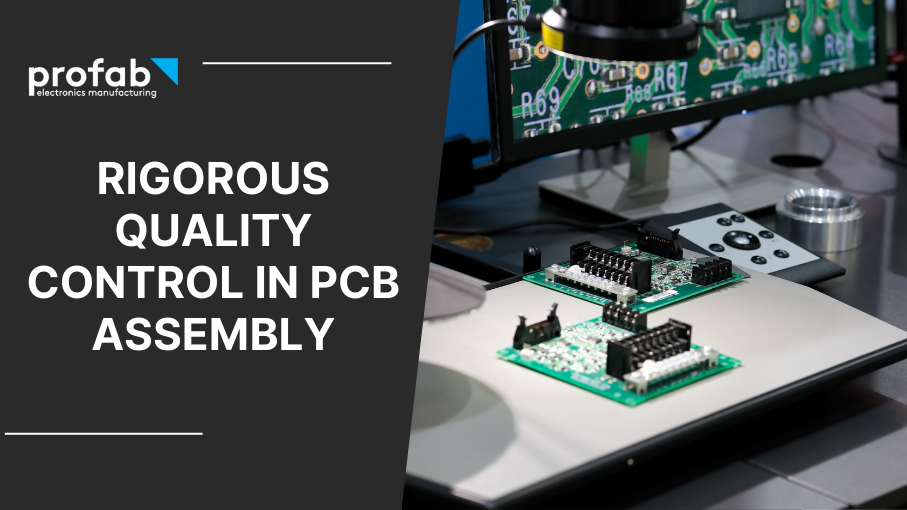

Automated Optical Inspection (AOI): Ensuring Perfection

In the realm of modern PCB assembly, quality control is of utmost importance. Automated Optical Inspection (AOI) systems play a crucial role in ensuring that each PCB meets the highest quality standards. These systems use advanced cameras and software to meticulously inspect PCBs for any defects, such as misalignments, missing components, or inadequate soldering. The ability to detect these issues early in the manufacturing process is vital in maintaining the quality and reliability of the final product.

At Profab Electronics, our AOI systems are seamlessly integrated into our assembly lines. This allows us to conduct real-time inspections and provide immediate feedback, ensuring that any issues are identified and rectified promptly. This proactive approach to quality control is fundamental to our philosophy. By ensuring that each PCB is thoroughly inspected and meets our stringent quality criteria before it leaves our facility, we uphold our reputation for excellence and reliability in the industry.

The Role of X-Ray Inspection in PCB Assembly

X-Ray inspection represents another layer of sophistication in modern PCB assembly. This technique is particularly valuable for inspecting areas that are not visible to the naked eye or AOI systems, such as underneath Ball Grid Array (BGA) packages. X-Ray inspection provides a detailed view of solder joints and component alignments, allowing us to identify defects that could otherwise go unnoticed.

At Profab Electronics, our X-Ray inspection capabilities enable us to maintain the highest standards of quality assurance. This method is particularly important for high-reliability applications where even the smallest defect can have significant consequences. Our ability to conduct such thorough inspections underscores our commitment to producing PCBs that not only meet but exceed the expectations and requirements of our clients.

Mastery Over Complexity

The modern landscape of PCB assembly is one of remarkable complexity and sophistication. At Profab Electronics, we have mastered this landscape, continually adapting and evolving to incorporate the latest technologies and techniques into our processes. Our expertise in SMT and THT, combined with our advanced soldering methods and rigorous quality control measures, positions us as a leader in the industry.

Through this overview of modern PCB assembly techniques, we hope to have provided a glimpse into the intricate world of PCB manufacturing and the expertise that Profab Electronics brings to this field. Our journey since 1993 has been one of continuous learning, innovation, and commitment to excellence, ensuring that we remain at the forefront of PCB assembly, ready to meet the challenges of today and tomorrow.

About Profab Electronics

Profoundly embedded in the electronics manufacturing sector, Profab Electronics has been steadfast in its commitment to deliver excellence for over three decades. Our unparalleled experience, fortified by our stringent quality standards, positions us as a trusted partner in the realm of Electronics Manufacturing Services (EMS).

We're an ISO 9001 and AS9100 certified company, and our adherence to these globally recognized standards attests to our unyielding quest for quality. Our team comprises experts who hold formative training on the latest IPC standards, ensuring that we consistently produce electronic products of the highest caliber.

Our proficiency lies in PCB assembly, offering a spectrum of services ranging from Surface Mount (SMT) to Through-Hole Assembly. From the initial stages of prototyping to high volume pcb assembly, we offer comprehensive solutions to meet client requirements.

At Profab Electronics, we synergize our expertise and experience to deliver high-quality electronic products. Our unwavering commitment to quality, innovation, and customer satisfaction has established Profab Electronics as a leader in the electronics manufacturing industry. Trust us to bring your technological visions to life.

Latest Posts

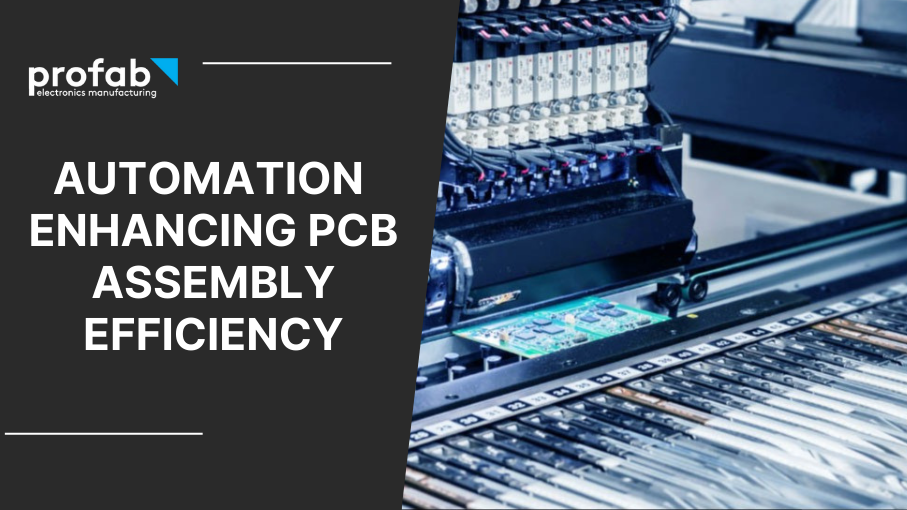

Learn about our state-of-the-art Surface Mount and Through-Hole Technologies, sophisticated soldering processes, and rigorous quality control methods that define today's industry standards.

Learn about our advanced component placement, solder paste printing, and automated inspection systems that revolutionize the assembly process.

Discover how our adherence to ISO 9001 and AS 9100 standards, IPC solder training, and meticulous inspection processes ensure the precision and accuracy of every PCB we produce, underpinning our unwavering commitment to quality.