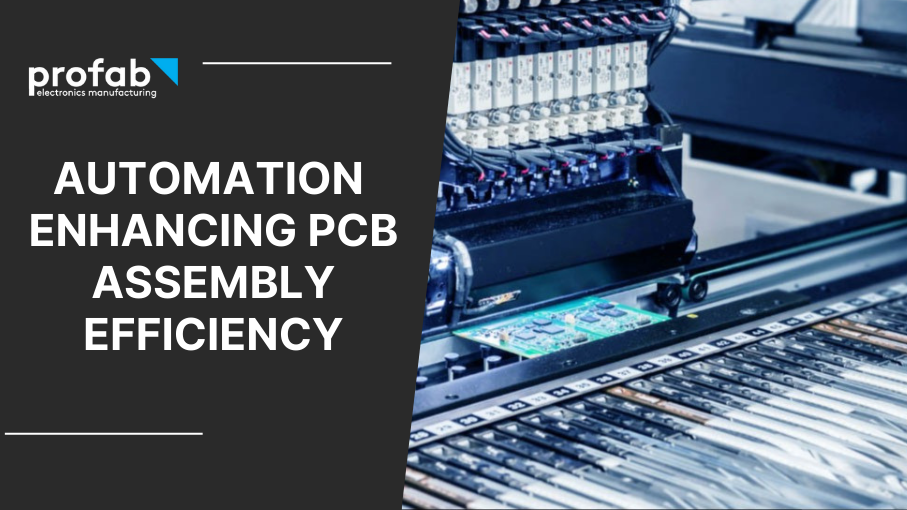

The Role of Automation in Enhancing PCB Assembly Efficiency

Learn about our advanced component placement, solder paste printing, and automated inspection systems that revolutionize the assembly process.

Embracing Automation in PCB Assembly

The landscape of Printed Circuit Board (PCB) assembly has been fundamentally transformed by the advent of automation technologies. Profab Electronics, since its inception in 1993, has been at the forefront of incorporating automation into our PCB assembly processes. This strategic decision has not only improved our efficiency but has also significantly enhanced the precision and quality of our products. In this article, we will explore the various facets of automation in PCB assembly and how it has revolutionized our production capabilities, leading to increased efficiency, reduced errors, and faster production times.

Automation in PCB assembly represents a paradigm shift from manual methods to a more streamlined, accurate, and efficient approach. The integration of automated systems has enabled us to handle the increasing complexity of PCBs while meeting the growing demands for faster turnaround times and higher-quality standards.

Automated Component Placement: Speed and Precision Combined

One of the most significant aspects of automation in PCB assembly is the automated placement of components. This process, which was once labor-intensive and prone to human error, has been revolutionized by the introduction of sophisticated pick-and-place machines. These machines are capable of placing components with incredible speed and precision, significantly increasing the throughput of PCB assembly while maintaining high accuracy.

At Profab Electronics, our state-of-the-art pick-and-place machines are a cornerstone of our assembly process. They are equipped with advanced vision systems that accurately identify component positions, ensuring precise placement on the PCB. This technology not only speeds up the assembly process but also reduces the likelihood of errors, which is critical in producing high-quality PCBs. For more insights into our component placement capabilities, please visit our article on PCB assembly component pick and place machines.

Solder Paste Printing: The Foundation of SMT Assembly

Solder paste printing is another critical process in PCB assembly that has been enhanced by automation. In Surface Mount Technology (SMT) assembly, applying solder paste accurately to the PCB is essential for ensuring good solder joints. Automated solder paste printers have revolutionized this process by delivering consistent, precise applications of solder paste.

Our automated solder paste printing machines at Profab Electronics use sophisticated stencil systems to apply the paste. These systems are highly accurate, ensuring that the right amount of solder paste is applied to each pad. This precision is crucial for preventing issues such as solder bridging or insufficient soldering, which can affect the functionality of the PCB. For a deeper understanding of this process, you can explore our article on solder paste printing for SMT PCB assembly.

Automated Inspection Systems: Guaranteeing Quality at Every Step

The role of inspection in PCB assembly cannot be overstated. Automated inspection systems like Automated Optical Inspection (AOI) and X-ray inspection play a vital role in ensuring the quality of PCBs. These systems provide thorough and precise inspections at various stages of the assembly process, identifying potential defects such as misalignments, insufficient soldering, or component placement errors.

At Profab Electronics, we utilize both AOI and X-ray inspection systems as integral parts of our quality control process. Our AOI systems are equipped with high-resolution cameras and advanced software algorithms that can detect even the smallest of defects. Similarly, our X-ray inspection systems allow us to examine solder joints and connections beneath components, ensuring the integrity of every PCB we produce. These automated inspection processes are essential for maintaining our high standards of quality. For more information, please refer to our articles on 3D Automated Optical Inspection and 3D X-ray inspection.

The Impact of Automation on Efficiency and Production Times

The implementation of automation in PCB assembly has had a profound impact on our efficiency and production times. Automated systems allow us to handle larger volumes of PCBs in a shorter amount of time, significantly reducing our turnaround times. This increase in efficiency is not just about speed; it also encompasses the ability to maintain consistent quality even at high production rates.

At Profab Electronics, our automated assembly lines are designed to maximize throughput without compromising on quality. The synchronization of automated component placement, solder paste printing, and inspection systems ensures a seamless and efficient production flow. This level of efficiency is particularly beneficial in meeting the demands of quick-turn production, where time is of the essence. You can learn more about our capabilities in this area in our article on quick-turn production PCB assembly.

Automation as a Catalyst for Excellence in PCB Assembly

Automation has undeniably become a catalyst for excellence in PCB assembly. At Profab Electronics, our embrace of automation technologies has enabled us to enhance every aspect of our assembly process, from speed and precision to quality and efficiency. This commitment to leveraging the latest technologies is a testament to our dedication to providing our clients with the best possible products and services.

As we continue to explore and integrate new advancements in automation, we remain focused on the goal of continuous improvement and innovation in PCB assembly. Our journey with automation is not just about staying ahead in a competitive market; it’s about setting new standards in efficiency and quality in the industry.

About Profab Electronics

Profoundly embedded in the electronics manufacturing sector, Profab Electronics has been steadfast in its commitment to deliver excellence for over three decades. Our unparalleled experience, fortified by our stringent quality standards, positions us as a trusted partner in the realm of Electronics Manufacturing Services (EMS).

We're an ISO 9001 and AS9100 certified company, and our adherence to these globally recognized standards attests to our unyielding quest for quality. Our team comprises experts who hold formative training on the latest IPC standards, ensuring that we consistently produce electronic products of the highest caliber.

Our proficiency lies in PCB assembly, offering a spectrum of services ranging from Surface Mount (SMT) to Through-Hole Assembly. From the initial stages of prototyping to high volume pcb assembly, we offer comprehensive solutions to meet client requirements.

At Profab Electronics, we synergize our expertise and experience to deliver high-quality electronic products. Our unwavering commitment to quality, innovation, and customer satisfaction has established Profab Electronics as a leader in the electronics manufacturing industry. Trust us to bring your technological visions to life.

Latest Posts

Learn how choosing the right materials and embracing newer technologies can lead to high-performance, reliable PCBs, and discover our collaborative approach to ensuring superior end products.

Discover the transformative journey of PCB assembly and Profab Electronics' pivotal role, from early innovations to today's advanced technologies.

From Selection to Quality Assurance: Navigating the Intricacies of Outsourced Production